110 mm Automated Test System

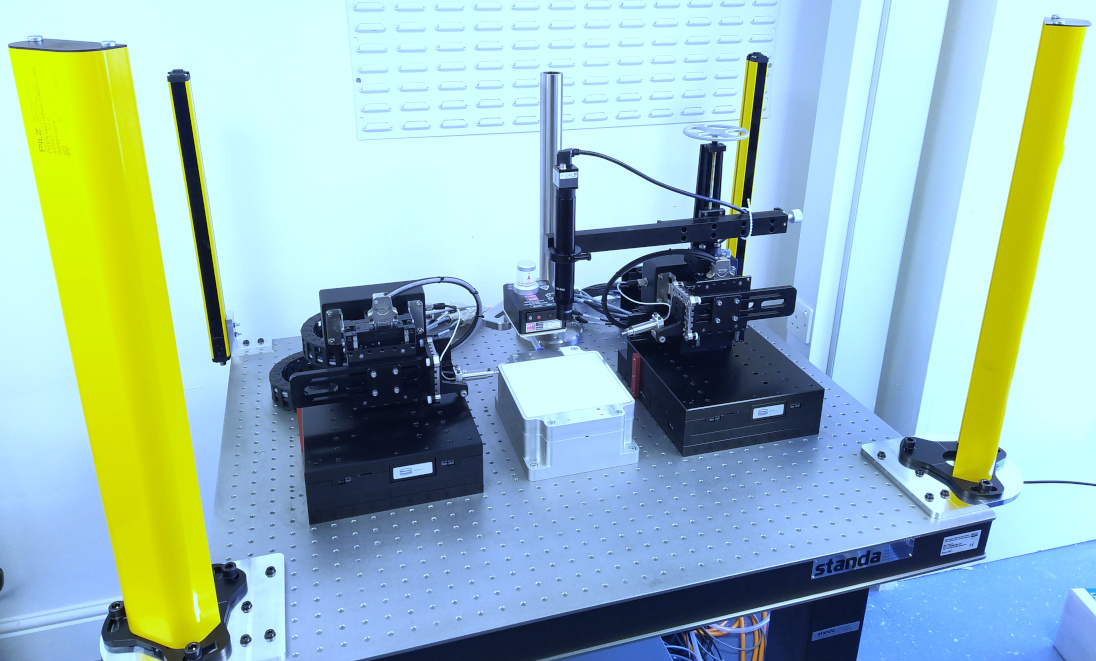

The ATS-8000G test system is a fully automated probing solution for HBM, TLP, VF-TLP, HMM and CC-TLP on package- and wafer-level.

Features

- Fully automated 110 mm probe station for for HBM, TLP, VF-TLP, HMM and CC-TLP on package-, system (PCB) and wafer-level

- Automation software remote control including:

- physical alignments (3D, multi-device)

- automatic BGA/QFP/DIL/etc pin map generator

- test definition and setup (e.g. ANSI/ESDA/JEDEC JS-001 table 2A, 2B)

- real time task view

- moving camera setup

- probe setup

- motion controller, pulse generator, SMU(s) setup and operation

- measurement data analysis and storage

- Flexible pitch 2-pin or fixed pitch 4-pin (Kelvin-type) probe arms

- Ultra-fast needle force touch-down sensors at [milli-Newton] force precision

- Automatic probearm and needle crash avoidance system

- Moving target camera

- Microporous vacuum chuck

- Safety shut-down light curtain (optional)

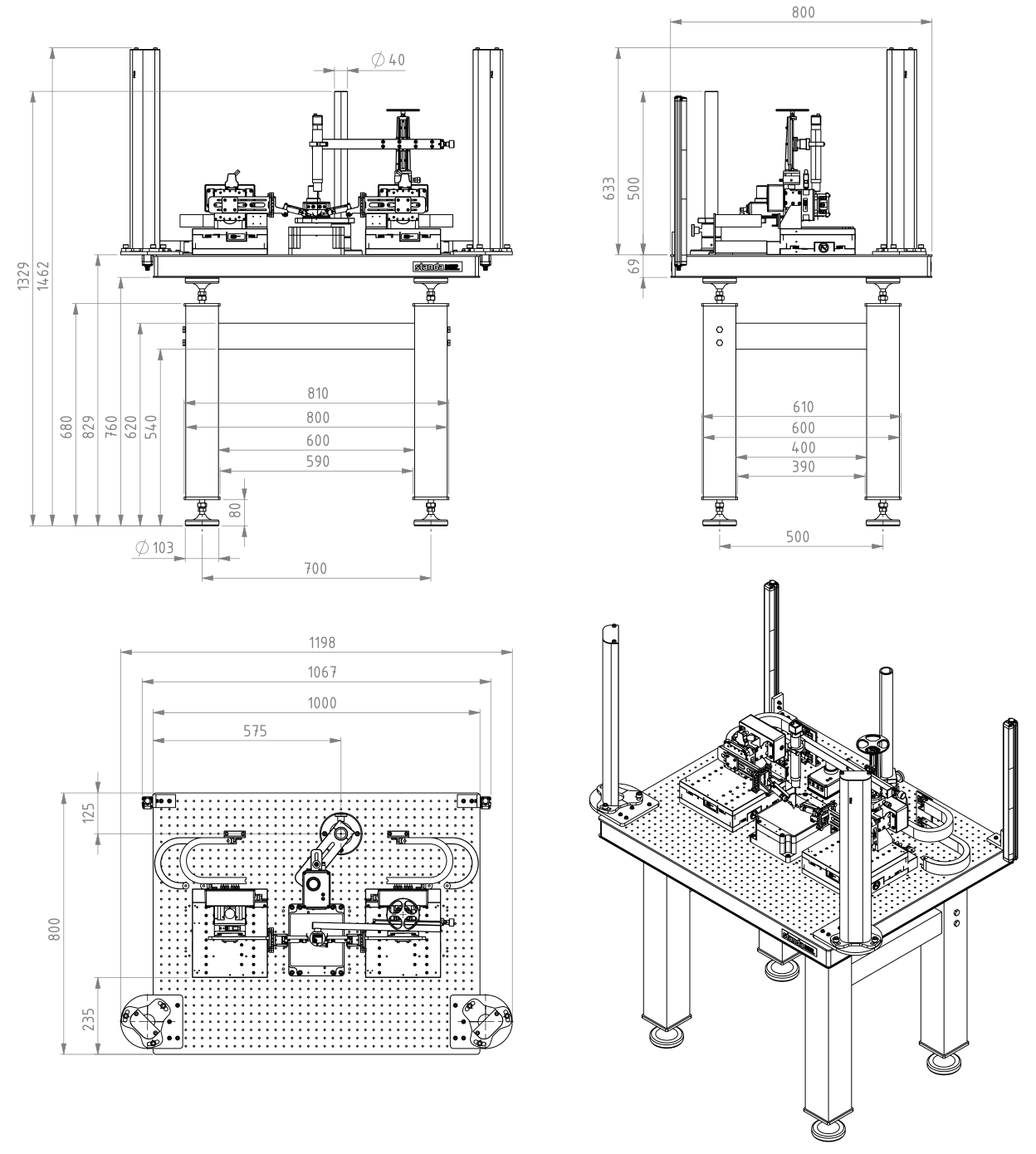

- Compact size: 1.2 m (width) x 0.8 m (depth) x 1.5 m (height)

- 160 kg weight

Downloads

Download: Product Datasheet ATS-8000G

System Components

| Item | Sub-Item | Qty. | Description | Model Number |

| 1 | 1.0 | 1 | Automated Test System | ATS-8000G |

| 1.1 | 2 | 110 mm X/Y-stages , linear scale encoder | XY110 | |

| 1.2 | 2 | 40 mm Z-stages, motor encoder | Z40 | |

| 1.3 | 2 | Probearm fixture platform 75 mm x 75 mm | PFP-75A | |

| 1.4 | 2 | Touch-down force sensors | TDS-A | |

| 1.5 | 1 | Microporous ceramic compound vacuum chuck 160 mm x 160 mm | VC-240A | |

| 1.6 | 1 | Moving target video camera system | MTC-18M | |

| 1.7 | 1 | Motion system controller | PL8885 | |

| 1.8 | 1 | Honeycomb breadboard 1000 mm x 800 mm x 70 mm | 707-0810-V1 | |

| 1.9 | 1 | Accessories fixture kit | AF-A | |

| 1.10 | 1 | Table support | 766-0507-AS | |

| 1.11 | 1 | HPPI automation software | ATS-OC |

Physical Dimensions [mm]

Note: Darkbox not included in ATS-8000G system.